Geomet and Dacromet

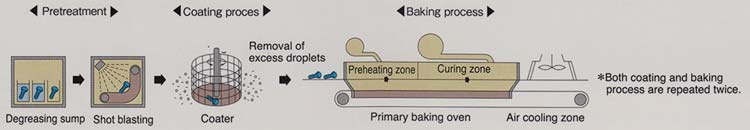

We are pleased to appraise you that we are doing "Geomet" and "Dacromet" zinc flake coating with Dip-spin/Spray process at Faridabad of various types of Steel Parts under Licence from M/s. NOF Metal Coatings Asia Pacific, Japan.

Our process is approved by almost all the major Automobile, Wind Mill and railways companies such as Maruti Suzuki. Honda, Toyota, Ford, Hyundai, Chrysler, BMW, GM, Diamler, Volvo, Tata Motors, Ashok Leyland, Gamesa Wind Mill, Inox Wind mill, BEML Railway coaches etc.

GEOMET & DACROMET is technologically advanced and environment friendly and is being used in many industries throughout the world, such as Automobile, Engineering, Electrical Appliances, Shipping, Railways, Mining, Process Industry, Military etc. since a very long time.

Various types of Top Coat is also available and done over Geomet and Dacromet coating to control COF values and enhance corrosion resistance.

Products offer several advantages such as:

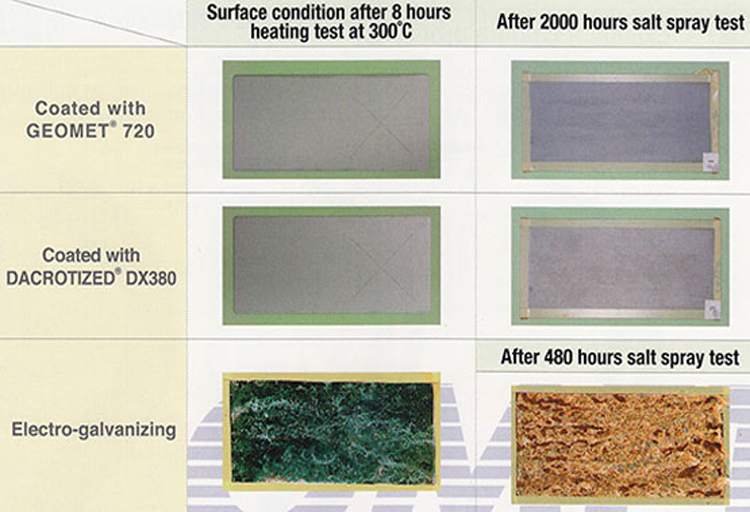

Excellent Resistance to Corrosion (5% Neutral salt spray life upto 1500 hrs)

Better Adhesion

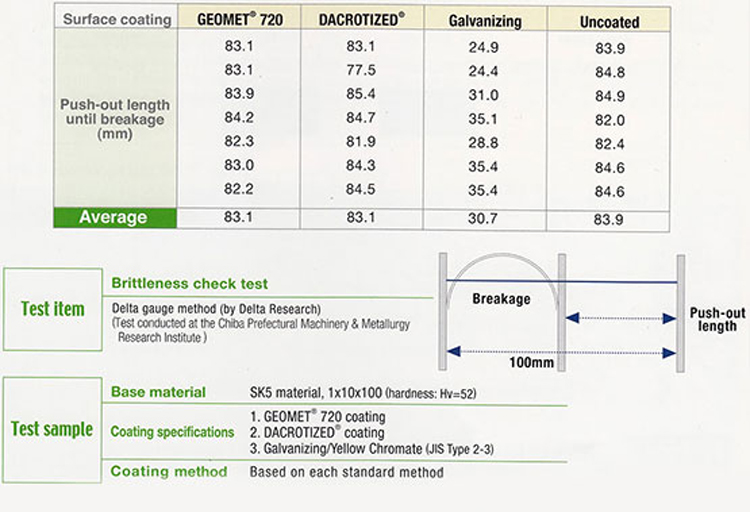

Completely free from Hydrogen Embrittlement

Heat Resistance (No effect on Properties of Dacro Coated Parts upto 280 deg. C.)

Resistance to Bimettalic Corrosion (Excellent performance when in contact with Aluminium, chromium, lead & zinc)

Pollution Free Process

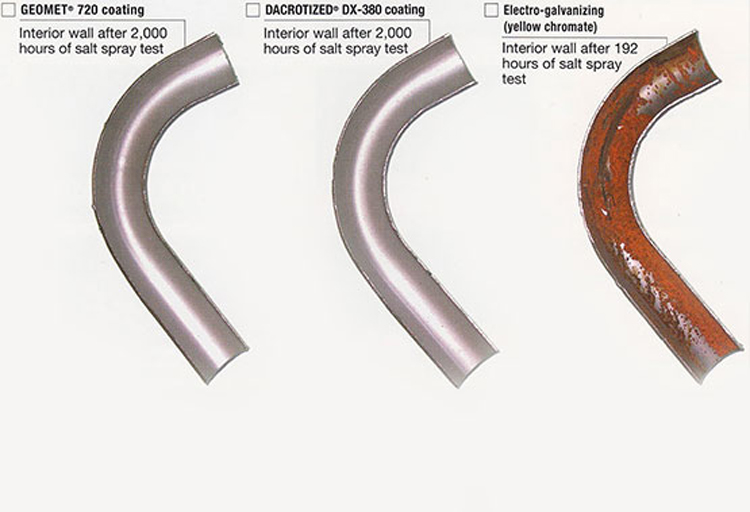

Overall coverage (Chemical penetrates in small crevices and gaps i.e. Springs, Inside of Pipe etc.)

Resistance to Organic Products.

Geomet® developed as a chromium-free solution to the environmental regulations enacted by the government and automotive industry. GEOMET IS ELV & RoHS compliance.

Geomet Coating

Dacromet Coating

Top Coat

COATING PROCESS APPROVALS